SBD CCM/CCB (Carbon Ceramic) Rotors + Brake Pads for R35 Nissan GTR

$2,599.95 – $6,999.95Price range: $2,599.95 through $6,999.95

-

Please call or email to confirm stock. We try to maintain stock for same day shipping.

Rotors are priced in 2 Pieces (1 Pair) or as a complete set of 4 Pieces.

- There are serial numbers on the rotors, make sure you install the rotor rotation properly as they have directional vanes. If the serial number is an odd number, that means the DRIVER side, an even number means the PASSENGER side.

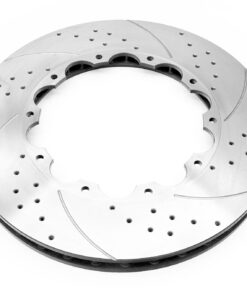

SBD is excited to unveil our new Carbon Ceramic Brake Rotors + Street Spec Brake Pads for the 2007-2024 R35 Nissan GTR.

- 100% PNP with ZERO Modifications Required in Factory Sizing.

- 50% Weight Reduction from your Factory Iron Rotors, which is a MASSIVE DROP in rotating mass for the drag strip & road track.

- For street cars, the advantages are 2-3x the lifespan of iron rotors, increased fuel economy from less rotational weight, and perhaps most importantly, near brake dust free experience.

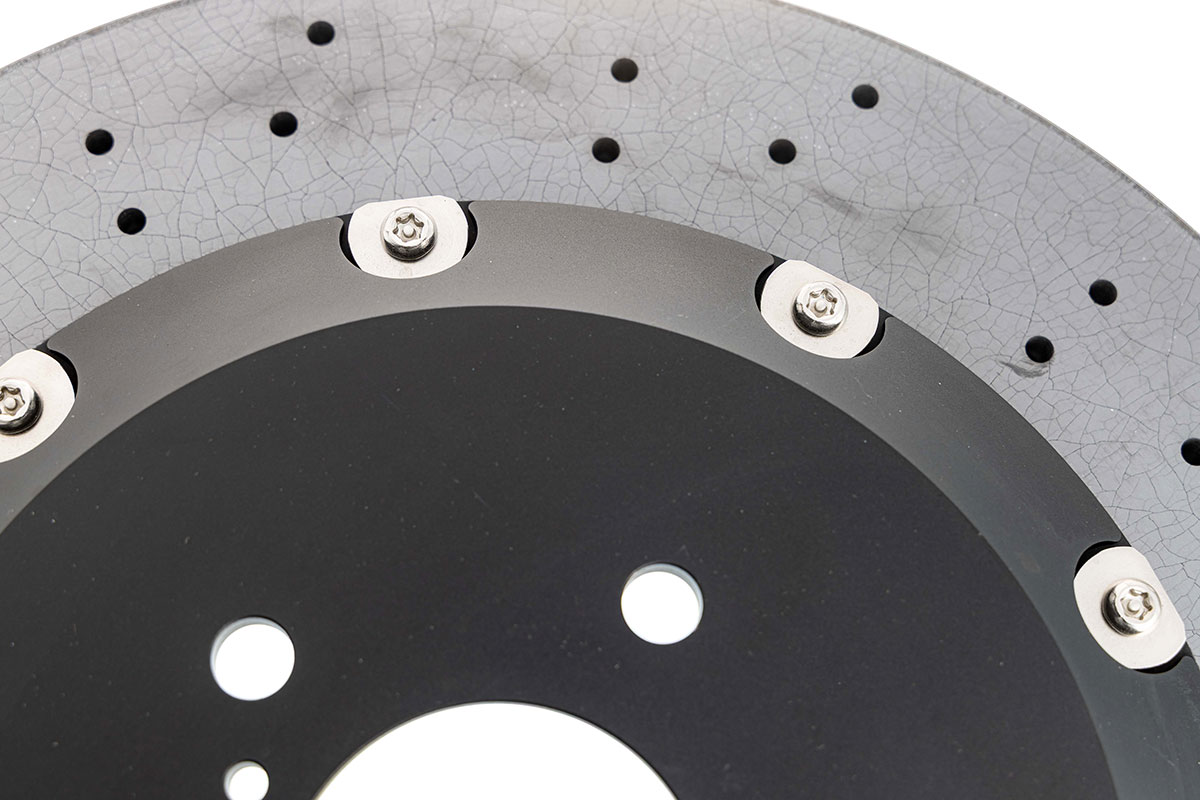

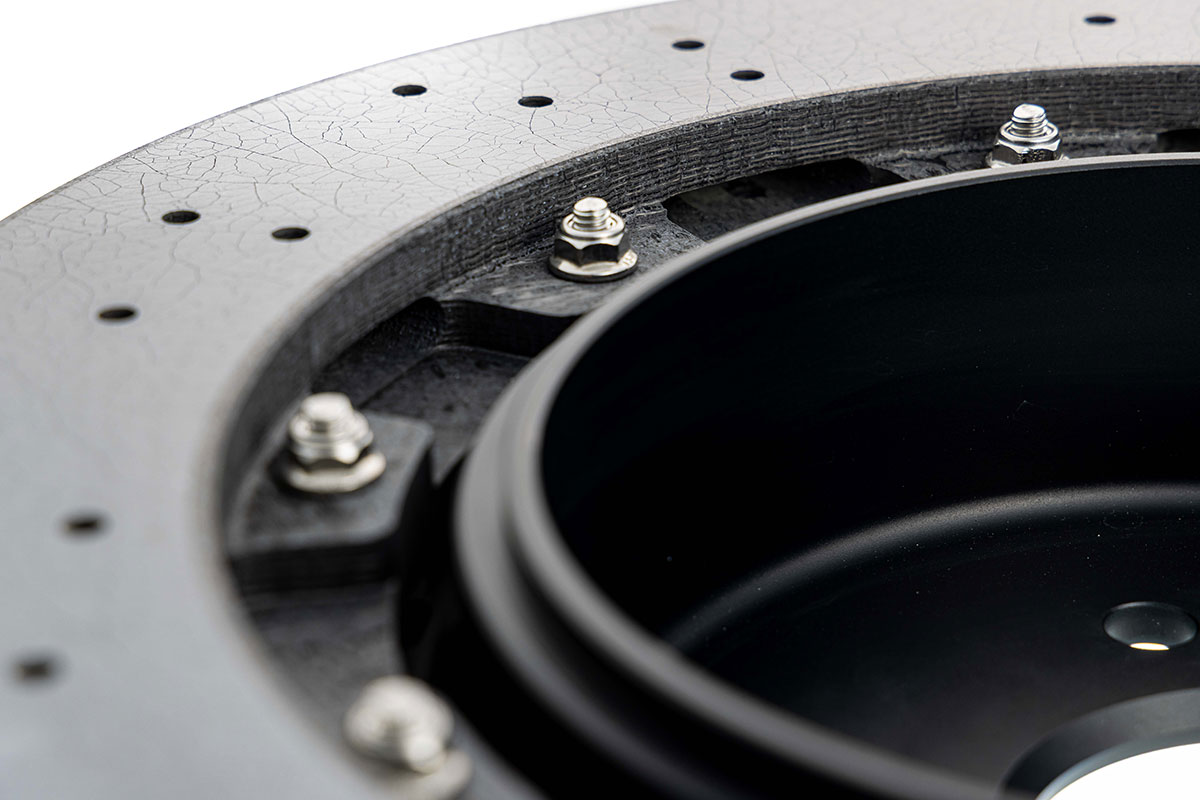

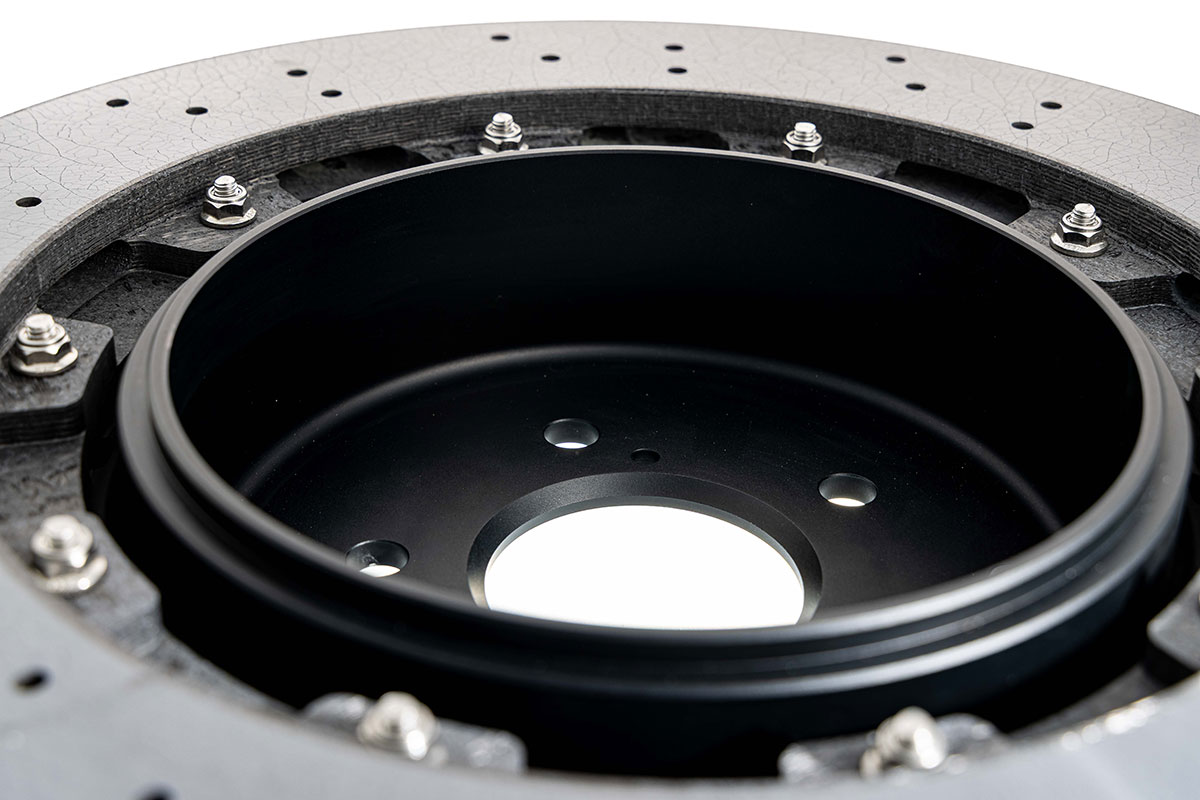

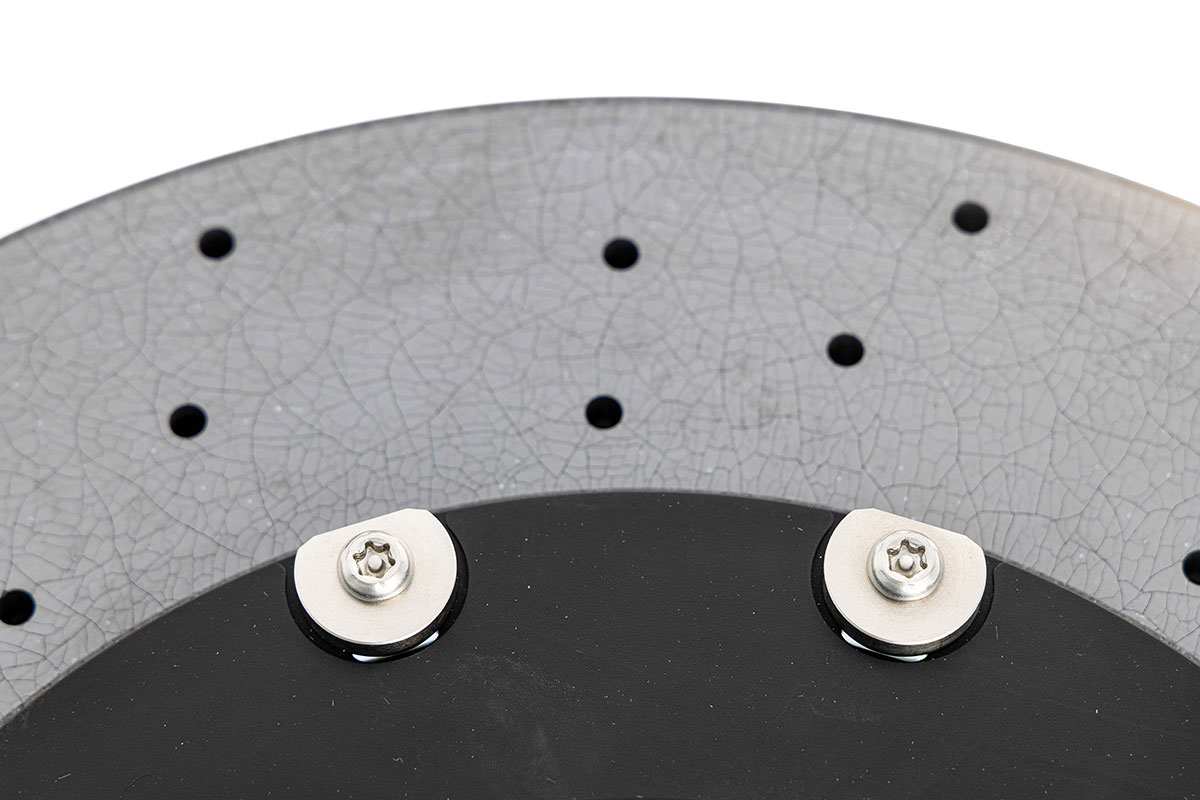

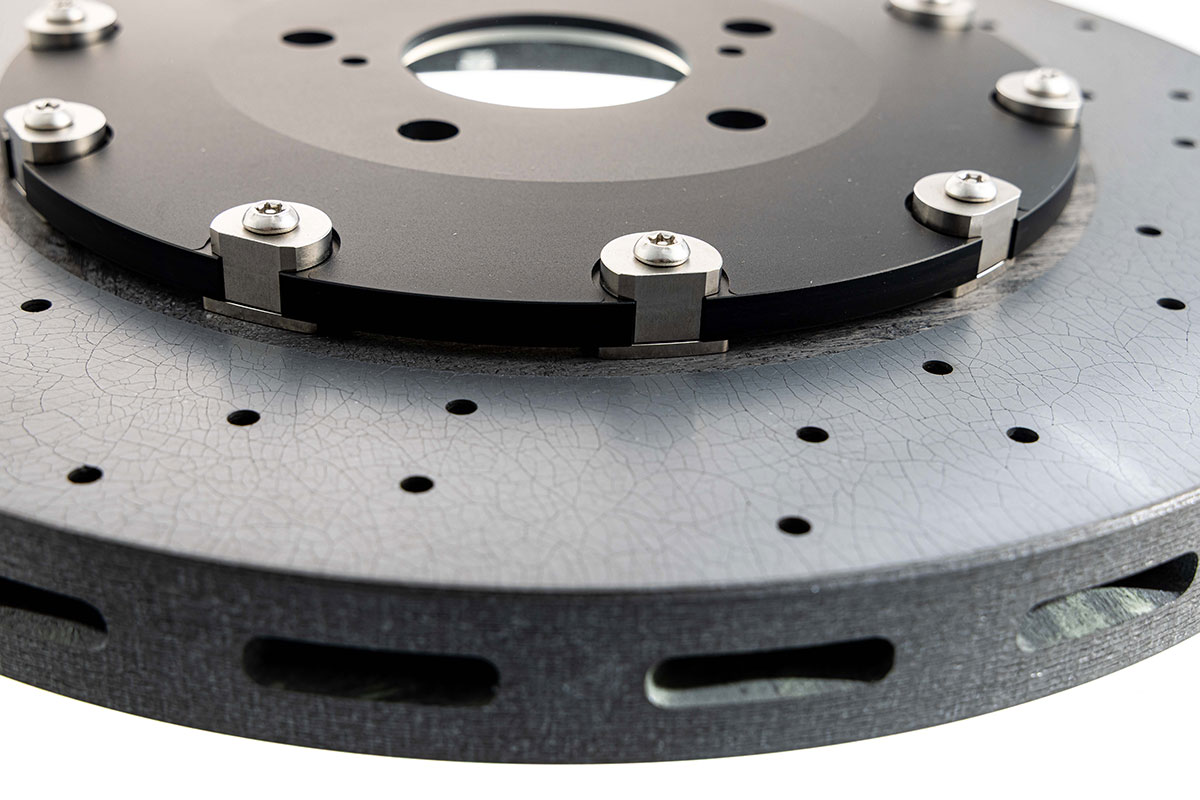

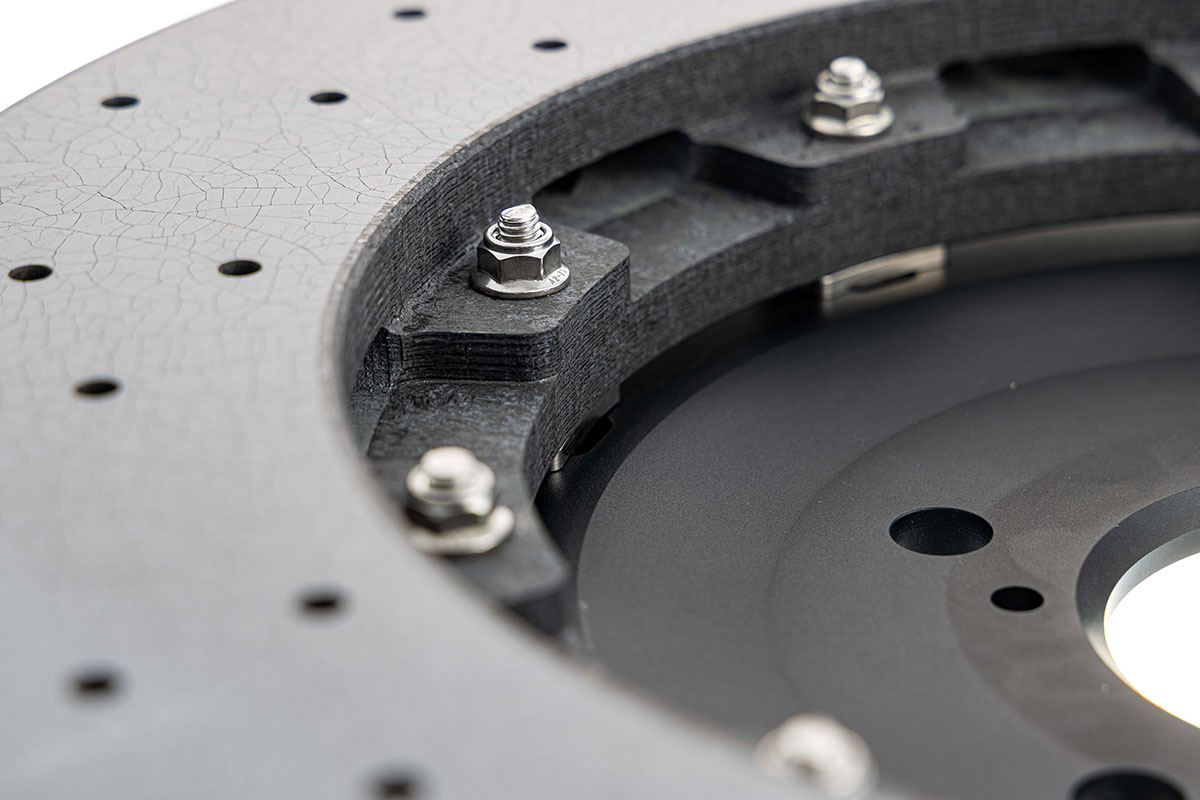

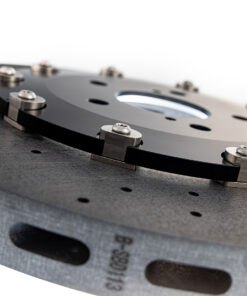

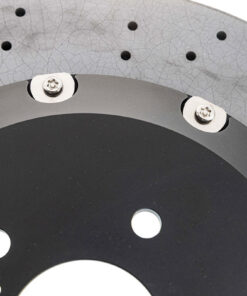

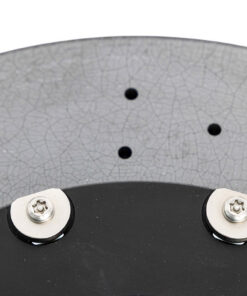

- Our Rotors include 7075-T6 Billet Aluminum Hats with NEW Bobbins Hardware. (Your factory hats & hardware may be discarded.)

- If you are a 2007-2011 CBA owner & wish to run 2012-2024 DBA Spec 390mm Front Rotors, we are happy to include the 6mm Caliper Spacers FREE Of Charge. ($145.95 Value)- Please request in order notes when placing order.

Rotor Sizes Available:

- 380mm Front Rotors for 2007-2011 GTR (CBA GTR)

- 390mm Front Rotors for 2012-2024 GTR (DBA GTR)

- 380mm Rear Rotors for 2007-2024 GTR (All Year Model GTR)

- 292mm Rear Rotors for Nissan 350Z Small Brake Conversion (aka 15″ Drag Wheel Conversion)

SBD Street Spec Carbon Ceramic Brake Pads Available:

- Front Brake Pads for 380mm/390mm Rotors (Fits All Year Models)

- Rear Brake Pads for 380mm Rotors (Fits All Year Models)

- Rear Brake Pads for 292mm Nissan 350Z Rotors (Fits All Year Models)

Note: If you have not upgraded to Stainless Steel Brake Lines, this is a MANDATORY upgrade when doing a Carbon Ceramic Brake Conversion.

SBD PTFE Stainless Brake Lines: $149.95/ Set of 4

- High Strength-to-Weight Ratio

- SBD’s Carbon Ceramic brake rotors only use T700 carbon fiber. T700 carbon fiber has excellent tensile strength (~4900 MPa) and a high modulus (~230 GPa), making it ideal for high-performance structural components. When used in rotors, this means better strength with less material, reducing overall brake mass. This helps lower unsprung weight and rotational inertia, leading to improved acceleration, handling, and suspension response. T700 rotors have ~40% higher tensile strength than T300-based rotors. This means they can withstand higher loads, faster heat cycling, and more aggressive braking without degradation.

- Superior Thermal Resistance

- T700 carbon fibers maintain structural integrity at very high temperatures. Carbon-ceramic rotors made with T700 can withstand operating temperatures over 1000°C without significant degradation. Normally, SBD’s T700-based CCM rotor’s highest temperature is around 500°C even for intensive street use.

- While both T300 and T700 have high heat tolerance (>1000°C), T700 composites are more stable under repeated thermal stress. This is crucial for:Consistent brake performance under repeated hard braking.

- Fade resistance during extreme driving conditions like track use or long downhill braking.

- Improved Heat Dissipation

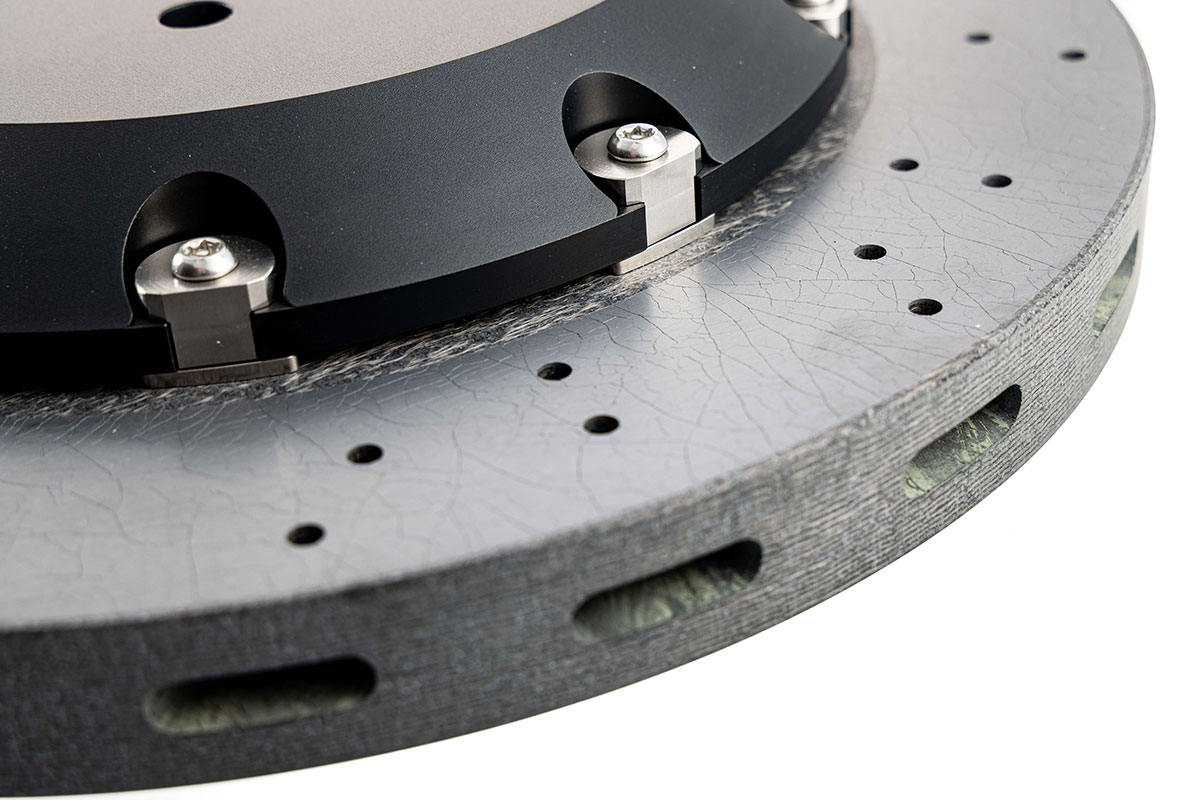

- The high thermal conductivity of carbon fiber composites aids in dispersing heat evenly across the rotor. Combined with ceramic matrix material (typically silicon carbide), T700-based rotors cool faster and are less prone to hot spots or thermal cracks compared to T300 and iron rotors.

- SBD’s Carbon Ceramic Rotors uses a special directional vane design for better heat dissipation. With this design, it has a 5%-10% faster cooling rate (from 500°C to cool down) than our competitors.

- Exceptional Durability and Longevity

- Carbon Ceramic rotors are known to last 3–5 times longer than conventional iron rotors under normal conditions. T700’s high fatigue resistance further improves this, especially in applications with frequent thermal cycling. This also reduces the total cost of ownership despite the higher upfront cost. The total longevity for normal use is over 350,000 miles.

- SBD’s Carbon Ceramic brake rotors have been tested at 7000 wheel rotation speed (equivalent to 300 MPH), and not damaged.

- Also, SBD uses Coated 7075 aluminum hats for better reliability. Below is a general comparison between 6066-T6 and 7075-T6.

| Property | 6066-T6 | 7075-T6/T651 |

| Ultimate Tensile Strength | ~310 MPa (45 ksi) | ~570 MPa (83 ksi) |

| Yield Strength | ~275 MPa (40 ksi) | ~505 MPa (73 ksi) |

| Hardness (Brinell) | ~95 | ~150 |

| Corrosion Resistance | Good | Fair (with coating will be better) |

| Machinability | Good | Excellent |

| Weldability | Good | Poor (prone to cracking) |

| Anodizing | Acceptable | Acceptable, but more difficult |

| Cost | Lower | Higher |

| Density | ~2.78 g/cm³ | ~2.81 g/cm³ |

- Weight Reduction = Performance Gain

- A single T700 carbon-ceramic rotor can weigh 40–60% less than a similar-sized iron rotor, and SBD’s T700(2.4 g/cm³) based rotors have a higher density (~1.80 g/cm³) than T300 CCM. The T700 carbon-ceramic rotor can reduce:

- Rotational mass, improves throttle response.

- Unsprung weight, enhancing suspension performance.

- Overall vehicle weight helps fuel efficiency or electric vehicle range.

- Corrosion Resistance

- Traditional steel or cast iron rotors can rust over time, especially in humid or salty environments. T700 carbon fibers embedded in a ceramic matrix are inert and non-corrosive, ensuring long-term reliability and aesthetics.

- SBD’s Carbon Ceramic rotors has been tested with an intensive Salt Spray experiment, condition 5% NaCl, ambient temperature at 35±2℃, and in a 480-hour continuous test, with no surface or weight changes before & after the test.

- Noise and Vibration Damping

- T700-based composites have better damping characteristics, which help reduce brake squeal and vibration. This provides a quieter, smoother braking experience, especially in high-end or luxury vehicles.

- Consistent Friction Coefficient

- Carbon ceramic rotors using T700 maintain a more stable coefficient of friction across temperature ranges compared to metal-based rotors.

- This translates to:

- Predictable pedal feel

- More linear braking performance

- Better modulation during high-speed deceleration

- OEM Level Manufacturing

- There are many Carbon Ceramic suppliers in the market, product consistency is an issue for smaller manufacturers.

- Our supplier is a Tier 1 OEM with decades of experience in the Carbon Ceramic industry, ensuring quality & safety is not compromised.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Rotor Sizes Needed | 380mm Fronts Only, 390mm Fronts Only, 380mm Rears Only, 292mm Rears Only, 380mm F + 380mm R, 390mm F + 380mm R, 390mm F + 292mm R, 380mm F + 292mm R |

| With SBD CCM Brake Pads | Yes, No (Rotors Only) |

| CCM or CCB | CCM, CCB |

Related products

All GT-R Products

-

Nissan GT-R 2007+ (R35)

-

Software/Tuning

-

All GT-R Products

-

All GT-R Products

-